MAH Centrifugal Slurry Pumps

•Pumping wear-resisting slurry or sewage •The wet parts made of high chromium alloy Cr30/Cr27/A05/A49(Wear resistance material) •Inlet:Axial •Outlet:Vertical •Connection method:Coupling or belt or gearbox • Grease or oil lubrication bearing assembly options offer ease of maintenance and reduced downtime • Optional dry running shaft seal reduces or eliminates flush water requirements • Effective expeller prolongs packing life while reducing or eliminating flush water requirement • Now featuring throatbush and impeller combination designed to enhance efficiency and improve wear performance • Interchangeability of seal arrangements – full flush, low flow, centrifugal, or mechanical seals may be fitted to any sized pump

hiddenValue

- Description

-

Technical data Scope of application Material Inlet diameter:50-400mm

Max flow:up to 2800m³/h

Max head:up to 110m

Max power:up to 1400kwPumping of abrasive and corrosive media

• Ball mill discharge

• Bottom/fly ash, lime grinding

• Coal

• Coarse sand

• Coarse tailings

• Dredging

• FGD

• Fine tailings

• Flotation

• Heavy media

• Minerals concentrate

• Mineral sands

• Ni acid slurry

• Oil sands

• Phosphoric acid

• Phosphate matrix

• Process chemical

• Pulp and paper

• Rod mill discharge

• SAG mill discharge

• Wet crushersImpeller:High chrome

Casing:High chrome

Shaft:45#

Mechanical seal: SS316+ SiCMAH series of pumps are horizontal, and double casing pump slurry pumps. The pump body and pump cover are equipped with replaceable metal lining, which is made of high chromium wear-resistant alloy material. The lining can be worn through until it is worn through, extending the maintenance period and reducing the operating cost. The outlet direction of the pump can be rotated and installed at 8 angles.

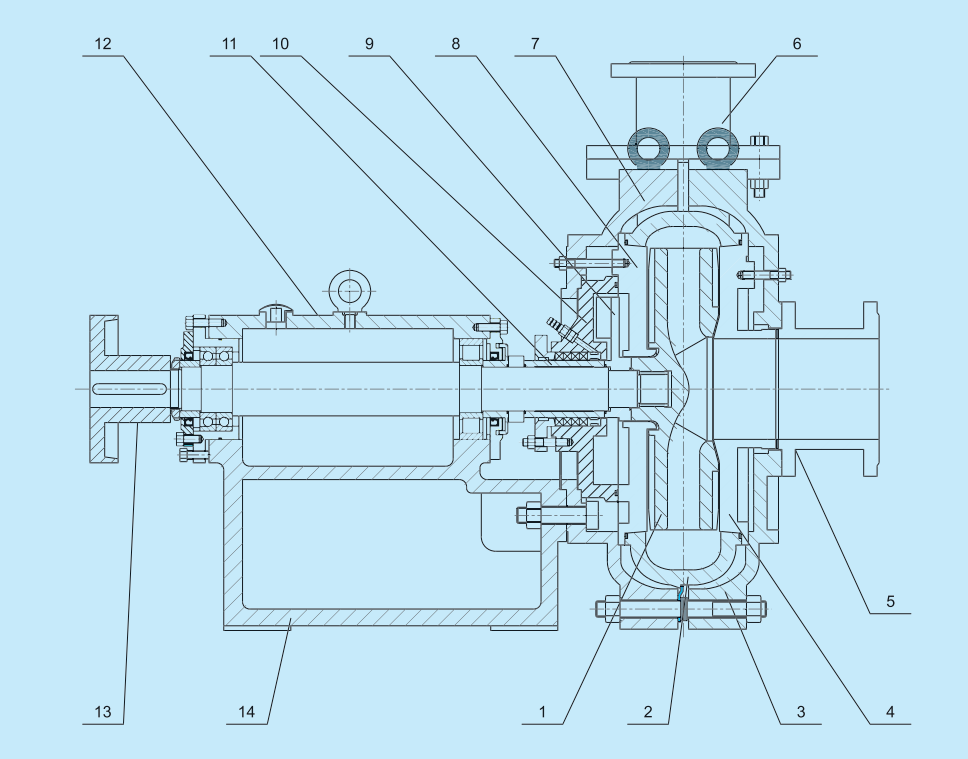

No Name Material No Name Material 1 Impeller Cr27/Cr30/Rubber 8 FPL insert Cr27/Cr30 2 Volute casing Cr27/Cr30/Rubber 9 Expeller Cast iron 3 Front housing Cast iron 10 stuffing box Cast iron 4 Throughbush Cr27/Cr30/Rubber 11 shaft sleeve 4Cr13 5 Inlet short pipe Cast iron 12 Bracket cover Cast iron 6 Outlet short pipe Cast iron 13 coupling Cast iron 7 Rear housing Cast iron 14 bracket Cast iron

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!