ZGMC Sic Slurry Pumps

•Pumping of abrasive and corrosive media •The wet parts made of industrial ceramic pump(Sic) •Inlet:Axial •Outlet:Vertical •Connection method:Coupling or gearbox •According to the wear performance test of the contrast material in the Institute of Wear-resistant Materials of the University, it is proved that the wear resistance of silicon carbide ceramic material is 3.15 times higher than that of high chromium alloy (Cr30). •The pump shell and guard plate lining are made of silicon carbide ceramic, and the external metal armor is used. The overall reliability of the pump is high, the safety is good, and the disassembly is convenient. •The special ingredients and process of ceramic materials ensure that the metal shell and ceramic lining are integrated and tightly combined. •The ceramic impeller is made of ceramic lined 316L stainless steel shaft head structure and silicon carbide ceramic material as a whole. The mechanical strength, wear resistance and corrosion resistance of the impeller are fundamentally guaranteed.

hiddenValue

- Description

-

Technical data Scope of application Material Inlet diameter:50-350mm

Max flow:up to 2700m³/h

Max head:up to 110m

Max power:up to 1200kwPumping of abrasive and corrosive media

• FGD

• Fine tailings

• Minerals concentrate

• Ni acid slurry

• Phosphoric acid

• Process chemical

• Pigment industry

• Fertilizer industry /

• Potash industryImpeller:Sic

Casing:Sic

Shaft:3Cr13

Mechanical seal: Duplex SS+ SiCZGMC industrial ceramic pump is manufactured by using the "ceramic+metal" composite manufacturing process. The core technology is based on the efficient hydraulic model of the metal pump, which is especially suitable for conveying highly abrasive and corrosive media.

Ceramic materials are professional and reliable. According to the characteristics of conveying slurry, the ceramic material with high strength, wear resistance and corrosion resistance is developed. The unique casting technology ensures the reliability of the combination of ceramic material and metal parts.

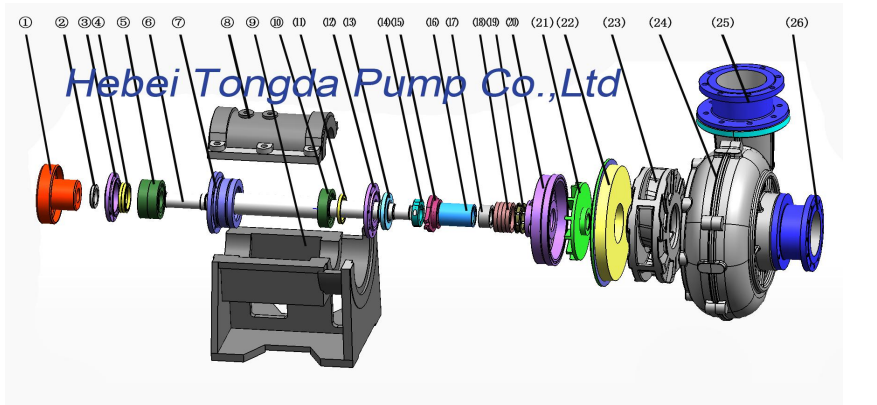

1.Coulping Pin coulping/Flexible coulping/Belt connection

2.Locknut Material cast iron

3.Front bearing cover Material cast iron

4.Oil seal Material Fluorine rubber(Long service life than normal material)

5.Ball bearing Brand SKF/NSK/HRB

6.Shaft Material 3Cr13

7.Bearing house Material cast iron

8.Frame cover Material cast iron

9.Frame Material cast iron

10.Ball bearing Brand SKF/NSK/HRB

11.Oil seal Material Fluorine rubber(Long service life than normal material)

12.Rear bearing cover Material 45#/SS316/Duplex SS

13.Water-Resistant Ring Material 45#/SS316/Duplex SS

14.Key Material 45#/SS316/Duplex SS

15.Packing cover Material 45#/SS316/Duplex SS

16.Bearing sleeve Material 45#/SS316/Duplex SS

17.Spacer sleeve Material 45#/SS316/Duplex SS

18.Graphite Packing

19.Water seal ring Material 45#/SS316/Duplex SS

20.Gland sealing box Material 45#/SS316/Duplex SS

21.Expeller Material 45#/SS316/Duplex SS

22.Protective plate Material Ceramic lining steel

23.Impeller Material Ceramic lining steel

24.Pump body Material ceramic wet parts,Cast steel casing

25.Outlet connection pipe Material cast iron lining ceramic

26. Inlet connection pipe Material cast iron lining ceramickeywords:- ZGMC Sic Slurry Pumps

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!