IH Chemical Pumps

• Pumping chemical liquid • The wet parts made of SS304/SS304L/SS316/SS316L • Inlet:Axial • Outlet:Vertical • Connection method:Coupling • Designed in accordance with ISO2858Standard; • Advanced and reasonable structure • High mechanical strength • Good sealing performance; • Good anti-cavitation performance. • Corrosion resistance and high temperature resistance • High reliability and long service life • Stable operation and high efficiency. • Convenient dismantling and repair

hiddenValue

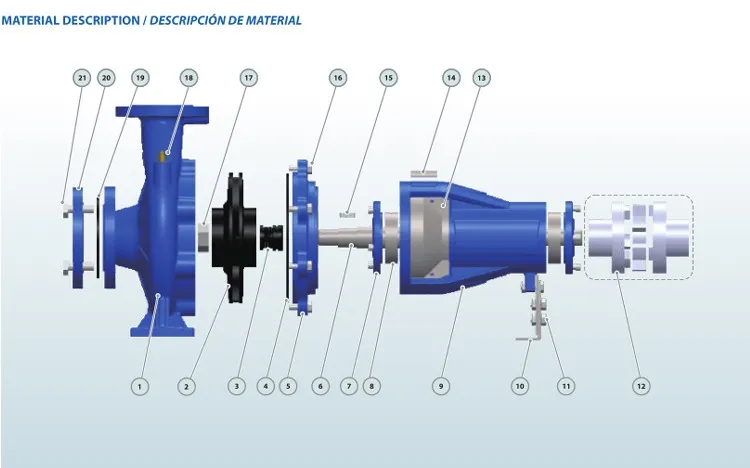

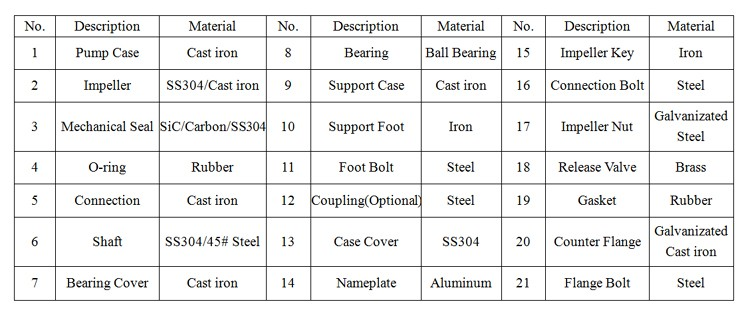

- Description

-

Technical data Scope of application Material Inlet diameter:50-250mm

Max flow:up to 500m³/h

Max head:up to 140m

Max power:up to 160kw* Chemical raw material industry

* Pharmaceutical industry

* Paper-making industry

* Paint, pigment and dye industry

* Pesticide and fertilizer industry

* Household chemicals industry

* Food and beverage industry

* Petrochemical industry

* Synthetic fiber manufacturing industry

* Washing agent and laundry detergent industryImpeller:SS304/SS304L/SS316/SS316L

Casing:SS304/SS304L/SS316/SS316L

Shaft:45#/3Cr13

Mechanical seal: SS316+ SiCIH chemical pump is a single-stage single suction (end suction) centrifugal pump, which is suitable for transporting corrosive liquids with viscosity similar to water without solid particles . IH chemical pump is designed in accordance with ISO 2858 End suction centrifugal pumps(rating 16 bar)-designation, nominal duty point and dimension. The temperature of the liquid should be - 20~105℃. It can pump higher temperature liquid if equipped with cooling measures. It is suitable for chemical industry, metallurgy, electric power, paper making, food, pharmaceutical,pesticide, dye and sewage treatment.

keywords:

keywords:- IH Chemical Pumps

Download

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!