TDSF Split Casing Pumps

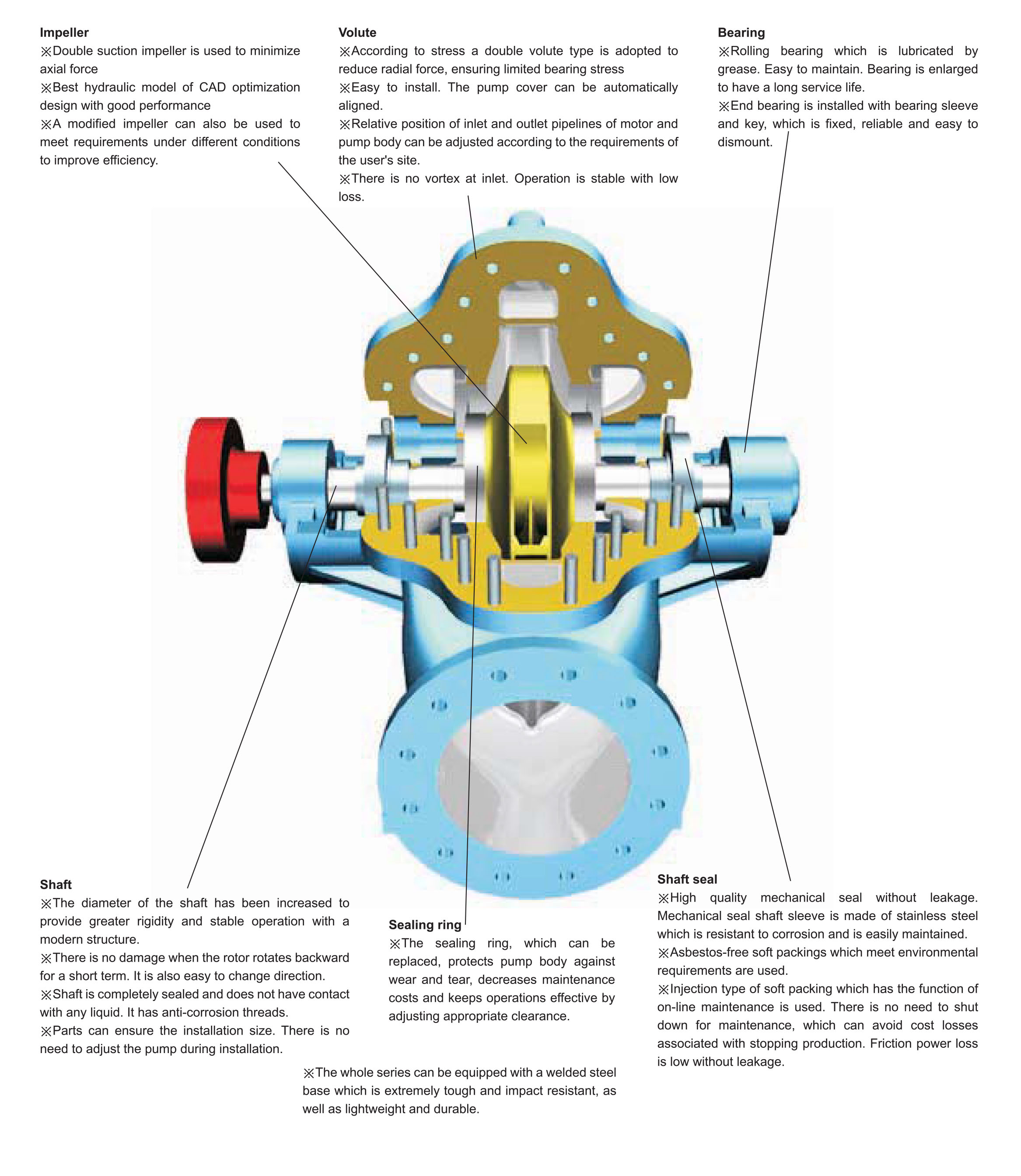

• Pumping clean water or similar liquid • The wet parts made of cast iron/cast steel/2Cr13/SS304/SS316 • Inlet:Axial • Outlet:Axial • Connection method:Coupling • Sealing of the upper and lower parts with O-rings ensures short maintenance times • Impeller with or without staggered blades (according to specific design) • Compact and robust bearing ensures ease of installation and long life • Replacement of seals without dismantling the casing • Split seal for short maintenance times

hiddenValue

- Description

-

Technical data Scope of application Material Inlet diameter:150-1000mm

Max flow:up to 17000m³/h

Max head:up to 155m

Max power:up to 2000kw• Coal mine

• Life water supply

• City water supply

• Industry water

• Power plant

• Cooling waterImpeller:Cast iron/Cast steel/SS304/SS316

Casing:Cast iron/Cast steel/SS304/SS316

Shaft:45#/3Cr13

Mechanical seal: SS316+ SiCTDSF SPLIT CASING Pumps

With efficiencies of up to 91%, TDSF Double-flow impeller axial split case water pump in-line casing for industry help to save valuable energy. All pumps are fitted with a double-flow radial impeller which achieves very favorable NPSH values. Due to the axial split case design, maintenance is fast and easy. Designed with a double-flow radial impeller and in-line casing, the pump can be installed horizontally or vertically (with horizontal installation, the motor can be placed on the left and/or right). These pumps can be used in a wide range of industrial processes. In the water sector, TDSF split case pumps operate in water treatment and water supply systems as well as in irrigation, flood control, and desalination. They can also be used as circulation water or cooling water pumps for power stations, industrial plants and district heating networks.

keywords:

keywords:- TDSF Split Casing Pumps

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!