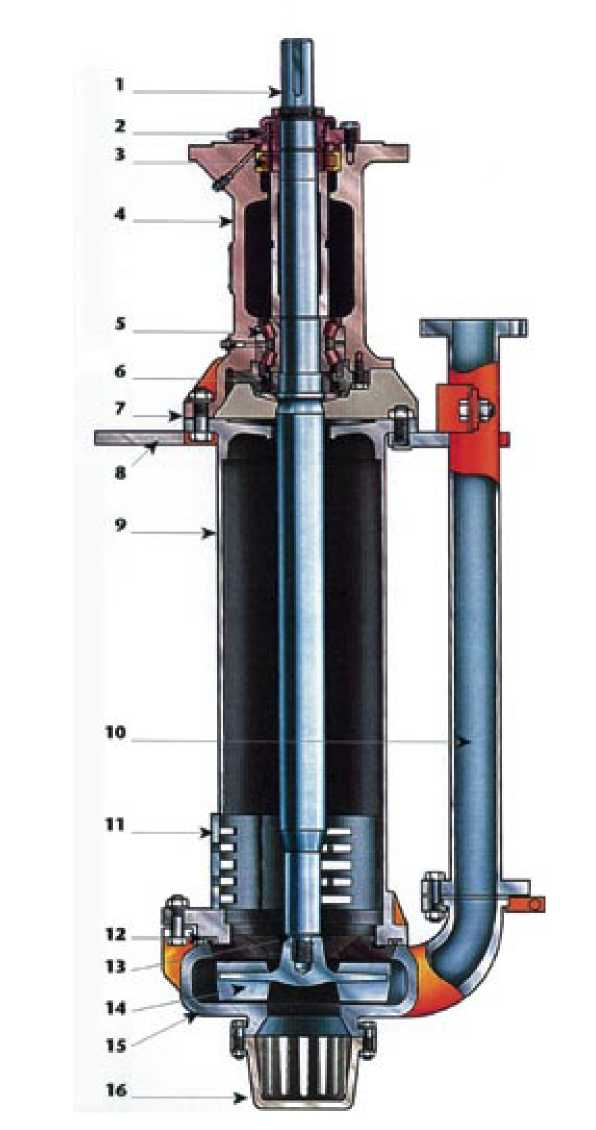

TLNH/TLFN Sump Slurry Pumps

•Pumping wear-resisting slurry or sewage •The wet parts made of high chromium alloy Cr30/Cr27/A05/A49(Wear resistance material) •Inlet:At the bottom of the pump •Outlet:Vertica •Connection method:Coupling or belt • Reliability - by design. • Low Spares costs - from longer wear life. • Lower Energy costs - from maintained efficiency. • After Sales Support - second to none. • Abrasion resistant A05 Ultrachrome alloy. • Abrasion/corrosion-resistant A49 Ultrachrome alloy. • Corrosion-resistant stainless steels. • Natural and synthetic elastomers.

hiddenValue

- Description

-

Technical data

Scope of application

Material

Inlet diameter:50-400mm

Max flow:up to 2800m³/h

Max head:up to 110m

Max power:up to 1400kwPumping of abrasive and corrosive media

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravelImpeller:High chrome

Casing:High chrome

Shaft:45#

Mechanical seal: SS316+ SiCThe strength of TD PUMP products lies in the superiority of our hydraulic designs and wear and corrosion resistant materials. TD PUMPS has invested heavily in an ongoing programme of research and development which focuses on the areas of hydraulic design, materials technology and shaft sealing. The TLNH/TLFN heavy duty cantilever sump pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer. The heavy duty cantilever design makes the TLNH/TLFN heavy duty sump slurry pump ideally suited for heavy continuous handling of abrasive and corrosive liquids and slurries whilst submerged in sumps or pits.

1.Shaft

Steel

2.Upper Bearing Seal

Labyrinth,piston rings and grease purge

3.Upper Bearing

Heavy duty grease lubricated parallel roller

4.Bearing Housing

Cast iron

5.Lower Bearings

Grease lubricated double taper roller

6.Lower Bearing Seal

Lip Seal and Flinger

7.Shims

Allow vertical adjustment of the impeller in the casing

8.Mounting Plate

TLNH-Steel/TLFN-Elastomer covered steel

9.Column

TLNH-Steel/TLFN-Elastomer covered steel

10.Discharge Pipe

TLNH-Steel/TLFN-Elastomer covered steel

11.Upper Strainer

TLNH-Stainless Steel/TLFN-Polyurethane

12.Back Liner Seal

TLNH-Elastomer

13.Impeller Thread Seal

TLNH-Elastomer

14.Impeller

TLNH-UltraChrome

TLFN-Elastomer moulded metal

15.Casing

TLNH-UltraChrome

TLFN-Elastomer moulded metal

16.Lower Strainer

TLNH-Polyurethane

TLFN-Elastomer moulded metalkeywords:- TLNH TLFN Vertical slurry pump

Download

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related